Copy Position

Material, as it passes/runs through a press is referred to as the press “web”, because it is “webbed” between a series of rollers as it passes through print, laminating, and die cutting stations. Label dimensions are referenced as “across the web” and “along the web”; the first dimension provided refers to the distance or dimension as it relates from one edge of the material to the other across the web while the second dimension references the distance or dimension as it relates to the direction the material is moving as it runs through the press, or comes off the roll along the web. The distance from point A of one label to point A of the next label is called the “repeat”. The repeat includes any gaps/spaces between labels. This information is critical during the engineering phase of label design because it impacts the cost as well as determines the direction labels come off the roll, referred to as “copy” or “unwind” direction. It is important to determine whether or not copy/unwind direction is critical, as new tooling may or may not be required.

For example, a “3 inch by 4 inch” label is orientated so that the label measures 3” across the web. This means that the overall width of the material of the finished label is approximately 3 and 1/8” wide, and that the label would dispense narrow end first.

This is important to the label converter for several reasons. First, the correct tooling is necessary to cut a label 3” across the web by 4” along the web. Most cutting dies cannot be altered on press. Obviously, if a converter does not own an existing die, one may be charged or built into the cost of the labels.

Another reason a label’s orientation is so important relates to the relationship between the information printed on the label and it’s position as the label comes off the roll. This is less important if labels are applied by hand (hand applied) but critical if automatically or semi-automatically applied by machine (machine/auto applied).

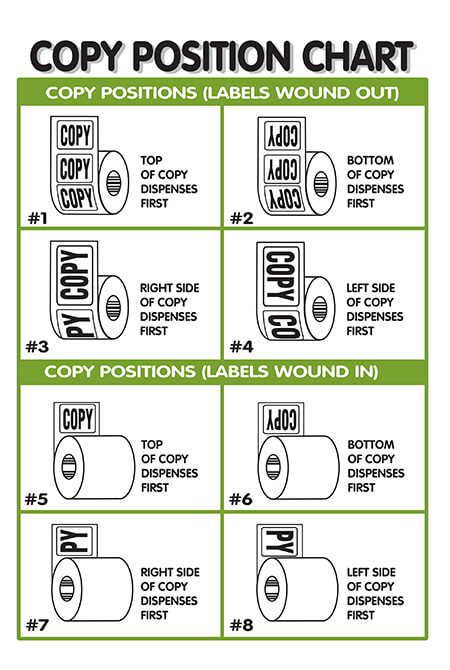

The “3 by 4” label used in our example would come off the roll narrow (3”) end first. If the information printed were positioned to read from left to right in the 4” direction, the label would dispense in copy (or unwind) direction #3 if reading right side up and copy/unwind direction #4 if reading upside down.

If, in the same example, the product and labeling equipment required that the 4” edge of the label come off the roll first, the label converter would ask whether the information printed should be orientated to come off the roll top or bottom first….copy/unwind direction #1 or #2 respectively.

Copy/unwind direction is often pre-determined by the product being labeled or labeling equipment being used.